Location Port Arthur, TX

Client Lamar State College Port Arthur (LSCPA)

Services Project Management

Project Value $7.9 million

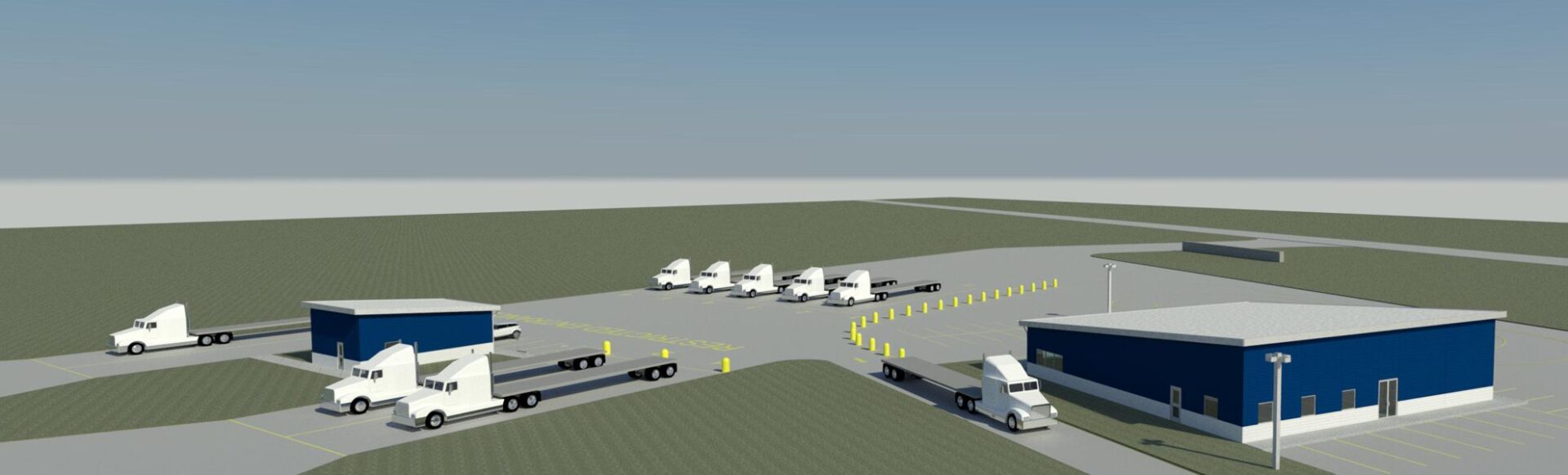

To promote job growth in Southeastern Texas and reduce the time it takes to test and certify commercial drivers, Lamar State College Port Arthur (LSCPA) is undertaking the Commercial Driver Education & Examination Center project. Once complete, the 24-acre Center will be the largest commercial driver training and testing facility in the state. The project includes two buildings, a 5,600 SF classroom and computer lab center with offices, student lounge space, restrooms, a registration desk, and a 900 SF examination lab with examiner bullpen space, restrooms, and mechanical and IT spaces. In addition, the Center will feature six parking lanes, four driving lanes, practice loops, loading docks, and railroad signage. LSCPA has plans to include tanker trailer loading stations, a functional tank farm, a rail tanker loading simulator, a maritime vessel tanker loading simulator, and more in subsequent project phases. The project was funded by the U.S Department of Commerce’s Economic Development Administration, local government, and a donation by the T.L.L. Temple Foundation

Hill International is providing project management services for the Center. Hill’s services include design review and validation, schedule and cost management, quality assurance/quality control, inspection, reporting, document control, and stakeholder coordination. Following construction, Hill will also support commissioning and closeout activities.

During construction, the team conducted flood mitigation to prepare the site for roughly 5,500 yards of poured concrete. Hill reviewed the design to promote compliance with State and local regulations and coordinated with the local drainage district to prevent any issues with the team’s mitigation efforts. In addition, as entrances to the project site encroach upon eight high-pressure gas lines, the team designed and constructed air bridges to avoid disrupting the lines. Hill coordinated with utilities to help prevent delays.