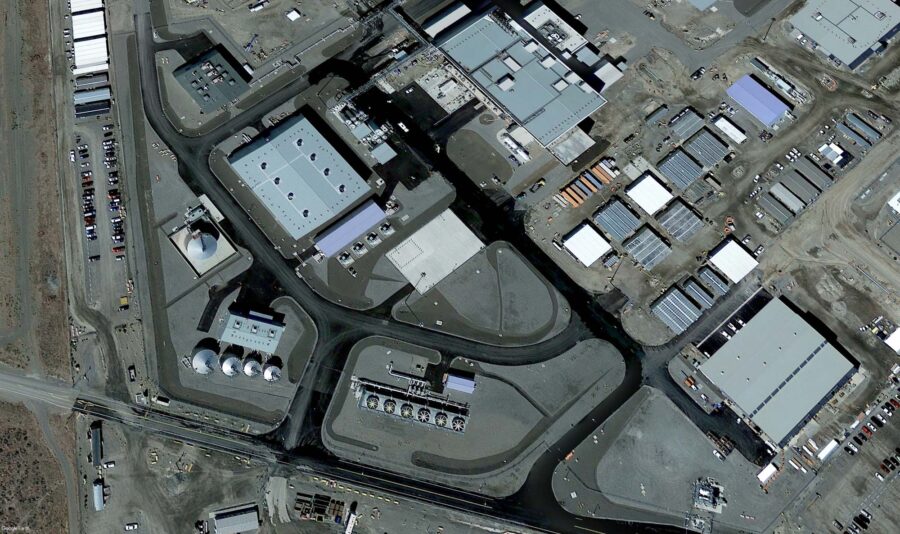

Location Southeastern Washington, WA

Client Department of Energy

Project Value $12.3 billion

Hill was responsible for managing a robust risk identification, analysis, and mitigation program for this project, which included both the Waste Treatment Plant and the Hanford Tank Waste Retrieval and Closure programs. The program that Hill administered addresses significant events (life-cycle risks) that have the potential to impact the scope, schedule, or budget for this 40-year, $2.5 billion a year program. The Hill team used state-of-the-art techniques, such as modeling project uncertainties using programs like Crystal Ball and PertMaster, to evaluate the potential impacts of project risks and focus management attention on the “critical risks” that threaten mission completion. The team also applied these techniques to evaluations of project “to-go” costs, analyzing the probability and level-of-confidence that the project could be completed within the current budget given uncertainties in key project variables such as quantities, pricing, and productivity.

Services provided by Hill included change control, risk management, performance assessment, and consulting support. Hill assisted Federal staff with the review and negotiation of more than $485 million in proposed baseline changes for the Plant. Our activities involved evaluating the technical merits of the proposal, the basis for the proposed costs, and alternative approaches to mitigate the cost impacts of the proposed change. Our support helped to reduce costs and keep work progressing.

In addition, Hill updated the Risk Management Plan in accordance with DOE Order 413.3. The update included identifying and quantifying new and existing project risks; developing risk management strategies and risk handling actions; and estimating the cost and schedule risk using Monte Carlo method modeling techniques. Hill developed an independent risk assessment in parallel with an assessment performed by the contractor to evaluate the potential that the project would overrun its current budget. This involved developing an independent Monte Carlo model in Crystal Ball that mimicked the results provided by the contractor’s proprietary risk assessment model, as well as evaluating engineering and construction productivity trends and their impacts on the projected estimate to complete.

During construction, Hill performed independent assessments to evaluate DOE and contractor performance on the Waste Treatment Plant Project, providing candid feedback to the Federal Project Director using a quantitative, industry-recognized tool that allows critical project performance parameters and project team behaviors to be trended and compared over time.

Finally, Hill led a team of outside experts who provided DOE-HQ staff and the Federal Project Director with recommendations for the restructuring and renegotiation of the Waste Treatment Plant Project contract. Hill provided research and recommendations on specific project management topical areas on an as-needed basis.

Hill assisted Federal staff with the review and negotiation of more than $485 million in proposed baseline changes for the Plant. Our activities involved evaluating the technical merits of the proposal, the basis for the proposed costs, and alternative approaches to mitigate the cost impacts of the proposed change. Our support helped to reduce costs and keep work progressing.

We and use cookies and other tracking technologies to improve your experience on our website. We may store and/or access information on a device and process personal data, such as your IP address and browsing data, for personalised advertising and content, advertising and content measurement, audience research and services development. Additionally, we may utilize precise geolocation data and identification through device scanning.

Please note that your consent will be valid across all our subdomains. You can change or withdraw your consent at any time by clicking the “Consent Preferences” button at the bottom of your screen. We respect your choices and are committed to providing you with a transparent and secure browsing experience.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |