Built to house the baking operations of the Wrocław Food Association (Breslauer Consum-Verein), the Mamut Bakery Complex on Sienkiewicza Street in Wrocław, Poland, was built in stages from the mid-nineteenth century through the 1920s. Today, Basecamp Student acquired this historic property with the intent to transform the Bakery into student accommodations and a six-story, four-star hotel for short-stay guests.

Grupa 5 Architekci designed the approximately 43,000 SM of the new and renovated area, creating a modern space for 775 student dorms, including 206 double hotel rooms and a wide range of multipurpose common spaces, including a 360 SM conference center, a fitness area, a restaurant, a lobby with bar, and an underground car park. General contractor Erbud used their expertise to develop Grupa 5 Architekci’s design in parallel with the execution of construction works. Hill International provided project management and multidisciplinary technical supervision services for the project, helping monitor costs, control schedule, and manage quality.

Basecamp envisioned a facility that served Wrocław’s large student population—the city boasts 11 public and 22 private colleges—with comfortable housing and plentiful amenities. However, mindful of the Complex’s history and prominent place on an arterial street north of the Oder River and the city center, Basecamp also wanted to preserve and enshrine some of the Complex’s historical architecture and unique features. The whole team worked together to deliver Basecamp’s vision on time and within budget in Q2 2022.

Before and After: Carefully Incorporating the Building’s Historical Features

“This is a building that has always responded to its times,” explains Hill Regional Manager Pawel Hrehorow. “The Bakery was built to meet bread demand during a period of growth for Wrocław, which was then called Breslau and was a part of Germany. In the late 19th and early 20th centuries, the city’s population tripled to more than 500,000. The Complex expanded several times in that period. The complex overall survived World War II, after which the city became a part of Poland. Now, Wrocław is famous for its universities and has a lively student and youth population. With this renovation project, Basecamp has given the facility a living role in Wrocław, while preserving and respecting the history of the Complex and the city.”

An overview of the Complex’s history sheds light on the features the team preserved and offers an opportunity to take a before-and-after look at the Complex. The Complex’s first facilities, a carbonated water factory and a steam bakery, were built in 1878-1880. Both facilities were destroyed during World War II. Due to the increase in the population and heightened demand for bread, Max Daum modernized and expanded the Complex in 1892-1893 and again in 1906-1908. The main production building, Building B, located on the northeastern part of the site and adjacent to the steam bakery building, comes from the latter period of development.

Building B was a three-story, steel-skeleton structure, covered by a high-hipped roof. Building B featured a red brick façade, as well as turret and globe decorations. The building’s rounded northeastern corner with its high chimney is a characteristic element of the period.

Building B’s production halls were located on the two upper floors. The ground floor was used as a loading hall. Glazed white brick lined the walls and ceilings of the interior rooms, and durable and functional cast-iron plates covered the floors.

The production halls were connected via staircase with the engine building, which held changing rooms and cloakrooms for employees. The engine building’s walls and ceilings also featured glazed white bricks. These featured orange decorative patterns.

Following the second round of expansion in 1906-1908, the Bakery Complex became one of the largest bakeries and mineral water factories in Germany. In 1913-1914 the facility expanded once again. On the south side of the existing production building, Alfred Doefert designed a massive six-story production building, Building A. This reinforced concrete structure featured a clinker brick façade and was almost completely preserved in its original form.

To maintain these design features, the team arrived at several period-appropriate methods. For façade veneering, the team used two types of ceramic fittings with head-and-stretcher-shaped dimensions. The contractor laid the ceramic fittings in a cross weft. The windowsills were executed in the form of a brick roll with an undercut along the lower edge (a rain drip). Thanks to the special shape of the façade, the use of profiled fittings, and the decorative use of regular fittings, the Complex maintains its appearance of plasticity.

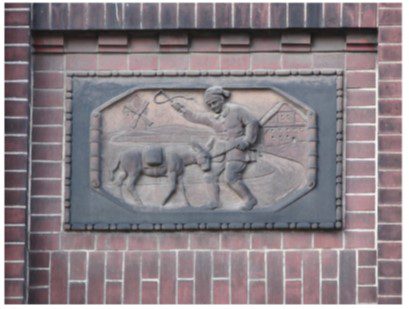

Six plates featuring sculptural reliefs depicting the bread production process adorn the front façade of Building A. Five of six reliefs are preserved: sowing, harvesting, grinding and transporting of flour, baking bread, and selling bread. The third element of the production cycle (likely grain threshing) was destroyed in 1945. On the 6th floor, another ceramic sculpture features a likeness, likely of designer Alfred Doerfert. The building’s plinths, as well as the frames of gates and entrances on the lower level are made of granite blocks. The preserved elements of the original décor and equipment include a steel door with an original handle, as well as window bars above the door of the front façade.

Following Alfred Doerfert’s design and expansion, in 1928 Building A received an additional four stories, arranged stepwise. In addition, a four-story passage was constructed to connect Building A to Building B. The passage is a reinforced concrete structure, one of the earliest examples of this technology in Wrocław. Also, during this period, Werner & Pfleiderer supplied the facility with two so-called “mammoth” ovens. This enabled a significant increase in the production of bread and gave the Complex a new moniker—”mamut,” which means mammoth in Polish.

Some of the Complex’s historical equipment survived the years and remains in the buildings. Grupa 5 Architekci incorporated some of this equipment into their design. In Building B, for example, part of an original “mamut” oven, the original elevator, original ironwork, and original cast iron plates are still in place. Two staircases, a changing room, and a bathroom have also been preserved in almost complete condition.

Building A also endured damage, especially to its roof and two upper floors, and the lower part of the façade was also damaged. During post-war reconstruction, ordinary bricks were used to restore façade damage. Profiled ceramic fittings were replaced with mixtures of cement and ground brick. The form of the upper floors was also changed. The roof, originally covered with black tiles, was re-covered with new red tiles. While not original, these repairs remain as an important reminder of the building’s and the city’s history.

After the war, the Complex was rebuilt, modernized, and continued to serve as a major bakery for the region until 2005. In 2008 the Complex was entered into Poland’s Register of Monuments as a recognition of its importance through the years and its survival during World War II. In 2010, demolition works were carried out on some of the preserved buildings, including the steel structure where the “mamut” ovens were located. Within the next ten years, Basecamp acquired the property and initiated its renovation project.

A Building of Its Time

“While the function of the Mamut Bakery has changed, its architectural character and unique features remain as testaments to Breslau’s growth, its devastation during World War II, and its rebirth as Wrocław, a hub for learning, youth, and culture,” adds Hrehorow. “The history and before-and-after photos presented here tell the story in a very small way, but hopefully they give an impression of the facility’s importance, both through the 19th and 20th centuries and, with Basecamp’s project, today.

“Basecamp has given the facility new life and preserved many of its important features, helping memorialize the names and circumstantial events surrounding the building’s history. Their project has been a source of pride for everyone on our team at Hill, Basecamp, Grupa 5 Architekci, Erbud, and other engaged parties. We’re proud to see it delivered, we’re proud to have delivered it successfully and see students and guests enjoying the new spaces.”

About the Author

Pawel Hrehorow serves as regional manager for Hill International’s operations in Poland and was engaged directly in the Basecamp Project. He has more than 20 years of experience providing project management and commercial services on projects throughout the country and abroad. He has worked on both private and public projects in multiple sectors including, residential, commercial, transportation, and manufacturing.

Pawel was supported on the Mamut project by the remarkable talents of Hill’s restoration team, consisting of Andrzej Jordan (Restoration Building Supervisor) and Piotr Wanat (Restoration Works Manager).

Share

June 23, 2025 | Articles

Jeffrey Hurley Joins Hill’s Northern California Rail Practice

June 23, 2025 | Articles

Ready, Set, Grow: First VP Chad Koelling Takes Charge of Hill’s Mountain West Region

June 8, 2025 | Articles

PMO in Saudi Arabia: The Holistic Approach to Realizing a National Mega-Portfolio

June 1, 2025 | Articles

May 26, 2025 | Articles

May 12, 2025 | Articles

Keeping Your Water/Wastewater Programs Flowing with Public Relations

April 27, 2025 | Articles

Oiling the Machine: Steps to Successful Permitting on Infrastructure Megaprojects

April 20, 2025 | Articles

Sustainable Scaling: Solutions for Managing Risk on Europe’s Data Center Projects